Developing critical insights on the effects of Mo on alpha prime precipitation and dislocation loop formation in FeCrAl alloys

Image by Y. Zhang (UW)

Image by Y. Zhang (UW)The Fukushima Daiichi incident raised the need for accident tolerant fuels (ATFs), including claddings, that have improved resistance to steam oxidation, reduced hydrogen production, and better retention of fission products in accident scenarios, while maintaining comparable performance during normal operation. As one of the leading long-term solutions, FeCrAl alloys have attracted extensive international attention for their outstanding oxidation resistance. However, their deployment is hindered by potential embrittlement caused by precipitation of Cr-rich 𝛼 at operational temperatures. While solid solutions such as Mo has been added to further improve the mechanical properties of FeCrAl at high temperatures, the impact of Mo on thermodynamics and kinetics of 𝛼precipitation in thermal conditions and on 𝛼 precipitation and dislocation loop formation under irradiation are unclear. The effects of Mo depend on various processing parameters including composition (e.g., Cr, Al, and Mo concentrations), aging temperature and time, and irradiation temperature, dose rate, and dose. Obtaining sufficient data in such a multi-dimensional design space remains a grand challenge for uncovering the effects of Mo and in general for nuclear materials development.

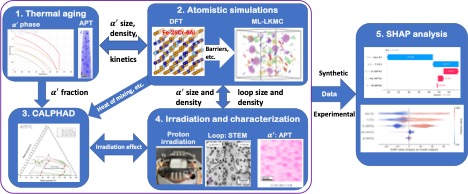

This project aims to develop a mechanistic understanding of the effects of Mo in FeCrAl alloys on 𝛼 precipitation in thermal aging and 𝛼 precipitation and dislocation loop formation under irradiation. The findings will be turned it into design principles for further optimization. Integrating the state-of-the-art modeling and experimental tools, we will first increase the throughput of harvesting experimental data in thermal aging and proton irradiation by using diffusion multiple samples with 12-25 wt.% Cr, 0-6 wt.% Al, and 0-4 wt.% Mo, to include the Generation-II (Gen.-II) FeCrAl alloys developed at Oak Ridge National Laboratory (ORNL) and the commercial alloys explored by General Electric (GE). Second, the experimental data will be used to validate a machine learning (ML)-driven lattice kinetic Monte Carlo (LKMC) model informed by ab initio density functional theory (DFT) calculations. Synthetic data will be generated using the validated model to thoroughly cover the design space defined by the processing parameters. An extensive database combing the new experimental and synthetic data with existing literature data will be constructed to perform Shapley Additive exPlanation (SHAP) analysis, which is an Explainable artificial intelligence (XAI) tool that can effectively extract the impact of each processing parameter including Mo concentration. Further, the effect of Mo on 𝛼 precipitation thermodynamics will be elucidated by computing mixing enthalpy and constructing phase diagram, and that on kinetics by computing elemental diffusivities and coupled solute-defect diffusion. Relating the effects of Mo to these basic material parameters will help extract design principles, to extrapolate the knowledge learned from Mo for identifying new beneficial solutes and solute combinations.

The proposed research addresses a critical challenge concerning the safety of current light water reactors. The novel research design and the modeling and experimental techniques will be transferrable to other alloy systems, to assist the discovery and development of novel materials such as advanced steels and high entropy alloys for applications in advanced reactors. Three graduate students will be trained via performing the cutting-edge research to support the future nuclear workforce.