Accelerated irradiation creep testing coupled with self-adaptive accelerated molecular dynamics simulations for scalability analysis

Image by L. Tan

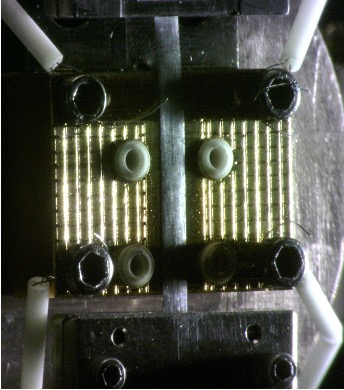

Image by L. TanThermal and irradiation creep are significant barriers to using conventional nuclear materials for elevated temperature advanced reactor concepts. A host of new materials and material systems are being proposed to increase the creep performance compared to traditional materials, but neutron irradiation creep testing, a key component towards qualification, involves high costs and long lead times that limit rapidly informed alloy and material design efforts. Recently, in-situ creep ion irradiation experiments have been proven as an accelerated surrogate for neutron irradiation testing with the significant benefits of being cheaper, faster, and do not induce long-lived radioactivity in the samples, making handling samples easier. Given this, previous efforts are still limited in the number of specimens and testing capability. In addition, the irradiation depth of common ion energies limits the scale-up to bulk-like behavior. This work proposes a solution to these shortcomings by using instrumented in-situ ion beam creep irradiations with tapered specimen geometries coupled to a self-adaptive accelerated molecular dynamics method (SAAMD). This approach will enable reasonable strategies for scale-up in both temporal and spatial dimensions based on evaluating the dominant creep mechanism(s) in the irradiated material. The approach will use a novel ion beam flux jump test (FJT) method on tapered creep specimens that will enable the observation of a materials creep response at varying dose rates (flux) and stress states during a single ion irradiation experiment in a single sample. The ion irradiations will be coupled with a post-irradiation microstructural characterization effort that will give us the experimental data to integrate and verify our SAAMD model to ascertain the functional irradiation creep mechanism(s). The use of tapered specimens will increase the number of stress states evaluated by three-fold or more throughout the project. The project will use conventional and additively manufactured Grade 91 as our reference and design material, respectively. The outcome of our novel project will be a rapid, low-cost accelerated method to understand and determine the fundamental creep mechanisms controlling irradiation creep in advanced material systems at the engineering scale.