Advance Castable Nanostructured Alloys for First-wall/Blanket Applications

Image by L. Tan

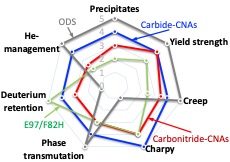

Image by L. TanThe objective of this project is to establish a US-RAFM (reduced-activation ferritic-martensitic) steel based on the carbide-strengthened Castable Nanostructured Alloys (CNAs) to demonstrate the viability and advantages of CNAs in the production and performance of industry-scale heats for integrated first-wall and blanket technology. A series of strategies are to help overcoming the challenges to be faced during the scale up study. Comprehensive examinations will be completed to evaluate the performance of these materials, with some of the results directly applicable for future code qualification of the CNA. State-of-the-art simulations will be employed to assist in scaling up heats production and experimental design and interpretation, as well as to provide physics-based support for credible extrapolation beyond the experimental results. A representative section of a helium-cooled sub-component will be fabricated as one of the project deliverables in addition to progress technical reports and several peer-reviewed publications.